Essential Things You Need to Know About Stainless Weld Cleaners

Share

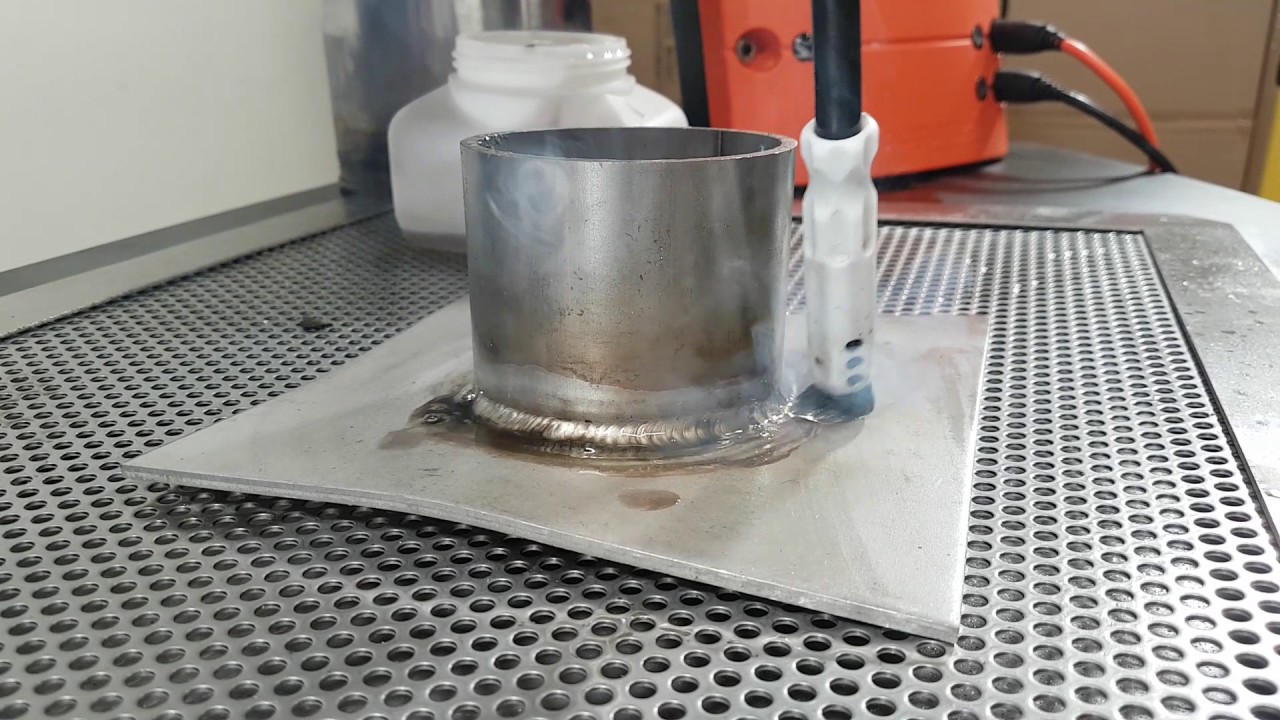

Whether you are a professional welder or simply a welding enthusiast that works with stainless steel, you are probably aware that metal gets tinted during the welding and heating process. This effect can drastically diminish your finished project’s aesthetic appeal and make it look ugly or unattractive.

This is why a stainless weld cleaner is important to ensure that your welding project maintains its appeal and attractiveness when it is finished. Despite the significance of weld cleaners, there are still welders who are not aware of their purpose. This article will talk about weld cleaners and the essential things you need to know about them.

Why the Need for Stainless Weld Cleaners?

Stainless steel has a natural oxide layer on its surface, thickening because of heat during the welding process. Depending on how thick the oxide layer is, more discoloration happens because of heat tint.

A welding project that has too much discoloration is not ideal because it will look unappealing. This is why a stainless weld cleaner is important. Using a weld cleaner, you can remove as much heat as possible to make your welding project look better.

Weld Cleaners Can Prevent Corrosion

Corrosion is a natural oxidation process. While preparing metal surfaces for welding projects, it is often exposed to atmospheric elements, such as oxygen and humidity, leading to rusting. Without proper cleaning and polishing of your welding projects, there is an increased chance of rusting, which is undoubtedly not a good thing.

Using weld cleaners to clean and polish your welding projects appropriately will help preserve the steel structure’s surface, strength, and shape. This is why weld cleaners are of the utmost importance because it allows the metal to perform to its optimum condition and level.

Different Categories of Weld Cleaning

There are different types of weld cleaning that generally involve brushing to prepare the steel and cleaning surface to remove particles. The following are the three main types:

Mechanical Weld Cleaning

This is the most common method when it comes to weld cleaning because it is a low-cost option. It typically involves abrasives and grinding machines that aim to clean the surface layer of your welding project. However, mechanical weld cleaning is not time-efficient and seldom achieves the desired results.

Pickling Paste Weld Cleaning

Pickling paste is a chemical that is widely used in weld cleaning. However, it brings more disadvantages than benefits. This is because pickling paste is quite toxic due to its chemical components.

Pickling paste is composed of toxic acids, such as sulfur acid, nitric acid, and hydrofluoric acid. Getting pickling paste on your skin can cause severe damage that might be irreversible.

Electrochemical Weld Cleaning

Electrochemical weld cleaning is widely considered the best method for cleaning weld projects. It offers a unique combination of electricity, heat, and chemistry that delivers astounding results than pickling paste and mechanical weld cleaning.

Not only is it effective for removing heat tints and corrosion on your welding projects, but it can also remove different kinds of impurities from several metal surfaces.

Conclusion

If you are passionate about your welding projects, you should not take weld cleaning lightly. Instead, it would be best if you prioritized investing in effective and efficient weld cleaners to make your welding projects look more aesthetically appealing. Check out a seller of electrochemical weld cleaners today, and start your journey of having attractive welding projects!